Why Custom Antibody Production Matters

How Monoclonal Antibodies Are Produced at Scale

Modern antibody production focuses on generating consistent, high-quality material from known antibody sources. Two primary platforms support this work: hybridoma-derived production and sequence-defined recombinant expression. These workflows begin only after an antibody hybridoma or sequence is established, forming the foundation for large-volume, high-consistency manufacturing.

Hybridoma-derived production centers on expanding a stable, well-characterized hybridoma cell line. When a hybridoma is provided or sourced, producers verify identity, confirm stability, and scale the culture under controlled conditions to generate antibody material with defined specificity. This approach remains widely used for antibodies originally generated through classical hybridoma technology. 1, 2

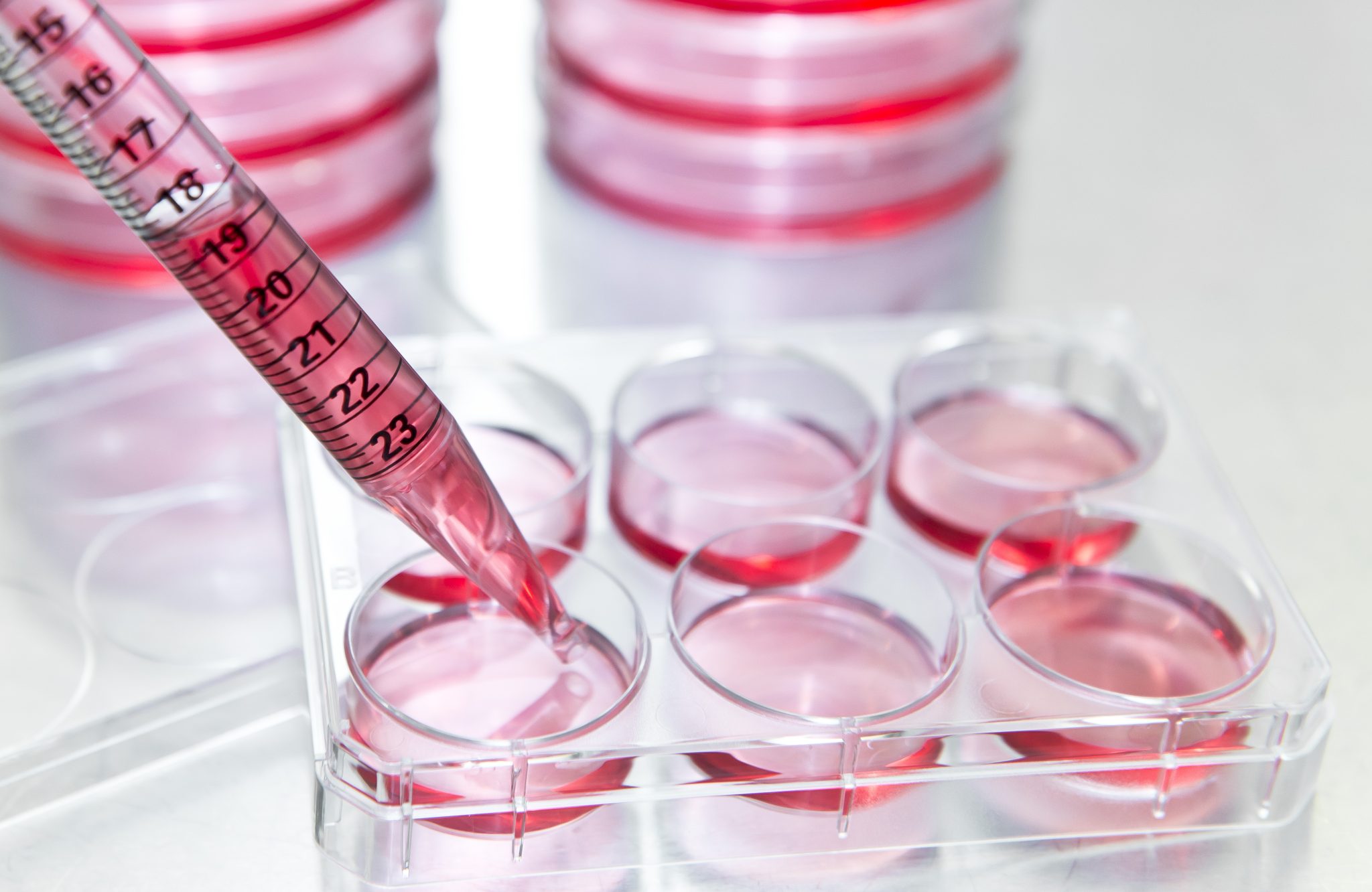

Recombinant production begins with a defined antibody sequence, whether obtained from a hybridoma, a published study, a sequence database, an engineered construct, or supplied directly by the research team. Once the sequence is available, it is introduced into a mammalian expression system such as HEK293 or CHO cells to generate antibody material with consistent characteristics across batches. 3

Across both platforms, successful scale-up depends on controlled bioprocess systems, robust production environments, and purification workflows designed to deliver high-purity material suitable for sensitive in vivo and advanced in vitro model systems. These requirements often exceed the capabilities of academic laboratories and smaller suppliers, particularly when multi-gram quantities or extended study timelines are required. As a result, many research teams turn to specialized production partners with the capacity, process control, and formulation expertise needed to support reproducible performance across long-term preclinical studies.

Why Antibody Production Quality Matters

Monoclonal antibodies support a wide range of experimental applications. In addition to detection and imaging assays, researchers rely on antibodies for functional studies such as cell depletion, pathway blockade, receptor activation, and immune modulation. These applications require high-quality reagents that perform reliably in living systems. 2, 3, 4

Several challenges can limit progress in many programs:

- Limited commercial availability or cost barriers when large study volumes are required, creating potential delays for programs that depend on consistent supply

- Formulations containing stabilizers, preservatives, endotoxins, or aggregates that complicate in vivo studies and necessitate cleaner alternatives

- Risk of lot-to-lot variability when antibodies are produced in small batches, affecting reproducibility and confidence in experimental results

- Limited access to conjugated or custom-formatted antibodies, constraining study design when specific configurations are required

For projects involving repeated dosing, longitudinal mechanistic studies, or multi-week in vivo experiments, production quality can determine whether a study advances smoothly or encounters delays. 4

Scalable Custom Manufacturing and In Vivo Study Success

Reliable antibody production workflows are especially important for preclinical in vivo research, where purity, formulation, and functional performance directly influence data quality and reproducibility. Addressing these challenges often requires production capabilities that provide greater scale, control, and consistency than most laboratories can achieve independently. As a result, research teams look for partners capable of producing high-purity material at scale, delivering consistent lots, and supporting specialized antibody formats required for sensitive applications.

Bio X Cell’s custom production capabilities are designed to meet these needs. Through hybridoma sourcing, isotype or species conversion, recombinant expression, and large-volume manufacturing, Bio X Cell produces in vivo-ready antibodies that support a wide range of preclinical models. 4

Antibodies are formulated in preservative-free PBS, screened for aggregation and pathogens, and produced with extremely low endotoxin levels appropriate for in vivo use. These attributes help support reproducibility across extended dosing schedules, multi-animal studies, and complex mechanistic experiments.

A Real-World Example: Supporting Polyomavirus Research

The value of scalable custom antibody production is illustrated in work by Aron Lukacher and colleagues at Pennsylvania State University. The group studies polyomavirus infection, a significant concern for kidney transplant recipients. Their research demonstrated that T-cell control of infection in the kidney depends on CXCR6 and CXCL16 signaling. 5

To investigate this mechanism, the researchers needed to block CXCL16 in vivo across multiple timepoints. Commercially available neutralizing antibodies were either cost-prohibitive, formulated with stabilizers unsuitable for mouse studies, or unavailable in sufficient quantities. 4

Bio X Cell sourced the original hybridoma and produced the required antibody in-house at the volume, purity, and formulation necessary for in vivo use. This enabled the researchers to test their hypothesis and advance findings relevant to transplant immunology. 4, 5

Why High-Quality Antibody Production Is Essential for Modern Research

Inconsistent or inadequate antibody supply can slow studies, complicate data interpretation, and limit experimental scope. In contrast, dependable access to high-quality, large-scale antibody production supports smoother project progression and strengthens reproducibility across studies. Custom antibody production provides researchers with the capacity, consistency, and flexibility required to pursue complex preclinical research and advance scientific programs with confidence.

References

- Marks L. The birth pangs of monoclonal antibody therapeutics. mAbs. 2012;4(3):403–412.

- Holzlöhner P, Hanack K. Generation of murine monoclonal antibodies by hybridoma technology. J Vis Exp. 2017;119:e54832.

- DeLuca KF, et al. Production and purification of recombinant monoclonal antibodies from human cells based on a primary sequence. Star Protoc. 2022;3(4):101915.

- Bushey K. Solving the antibody access problem in translational research with custom services. Bio X Cell. 2025.

- Lauver MD, et al. The CXCR6–CXCL16 axis mediates T cell control of a polyomavirus infection in the kidney. PLoS Pathog. 2025;21(3):e1012969.